I asked trusted friend and experienced auto restorer Mike Smith to spearhead the partial restoration and modification of my full-scale Club Victoria. The engine in the car had been making some very troubling noises and it seemed reasonable to pull the engine from the car to determine source of the ugly sound coming from the engine. Also, the Vicky’s motor compartment and front suspension were a greasy, sticky, dirty mess and needed to be cleaned.

So, off came off the hood,

the engine came out of the car and Mike completely disassembled it, and discovered a partially-spun crank bearing – explaining the bad sound. Mike sent the engine parts out for hot-tanking to remove grease and paint. The engine was bored .030, new 9:1 Jahn’s Sealed Power forged pistons were purchased, the rotating assembly was balanced and a fresh, but mild, performance cam was specially-machined by famed grinder Chris Nelson, The heads were freshened and treated to quite a bit of bowl work and port matching (and valve seat hardening), and cut .030 to increase compression.

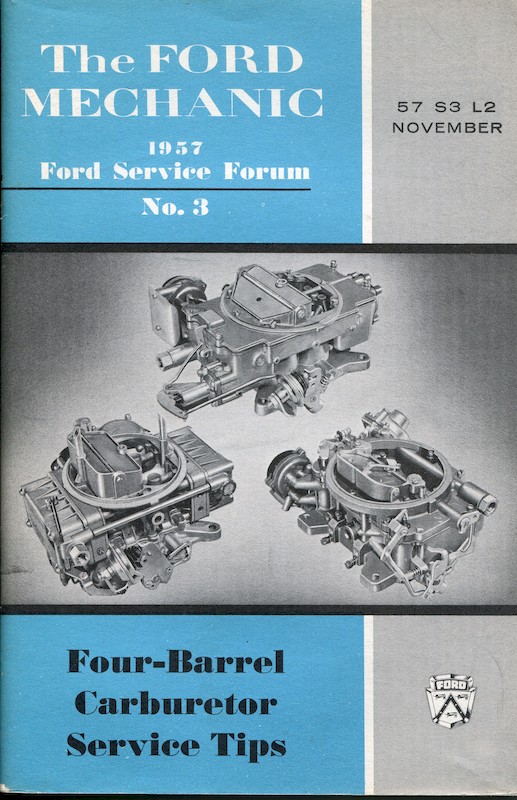

Though this 292 Y-Block engine was factory-built with a small 2-V Holley carb (that constantly leaked) fitted to the standard-issue factory 2-V intake manifold, I found a very rare Autolite Model 4100 large venturi (1.19) four-barrel carb on Ebay that was once fitted to the high-performance 1958 Mercury 383 AO1 engine. Though little-known, the Ford 4100-series carb was installed on ‘57 Fords as confirmed by this factory brochure,

but this large venturi 400 carb was not used on any factory-produced ‘57 Ford. This Ebay-sourced carb is the largest venturi Autolite carburetor that Ford ever produced (the company otherwise relied upon out-sourced Holleys for the most part). Ultimately (when we decided to modify the engine), Mike Smith also procured a beautiful, one-off prototype set of tubular steel headers

from Chris Nelson that we had ceramic-coated; coupled with a low restriction exhaust system with an “H” pipe, a four-speed, and twin large angle-tip cut reproduction ‘67 Shelby angle-cut exhaust tips, this car should really scoot. We had originally intended to use the restored ‘57 three-speed transmission, but opted for the later Ford 4-speed. This engine work required several months of intermittent, part-time work the long duration of which was caused, in part, by the difficulty in getting vintage engine parts, waiting for the special cam as well as a significant/on-going budget limitation.

Mike carefully reassembled the engine and expertly painted it with the correct bright red color that Ford applied at the factory. Of course, both the engine (on a technical level), and its paint and detail, are much better built and detailed than could ever have been found on a factory-fresh car and that’s okay – I frankly like mildly over-restored cars!

At this point, though the engine appeared factory stock from the outside, it has been significantly modified internally – with more changes to come!

February to May 2013: The Project took a hiatus while Mike hunted parts and I prepared for the 24th GSL Championship.